'ETU-GRIFFON' Turbofan Aircraft Engine Designed by TOBB ETU Students was the First in Teknofest Competition

2019

TOBB ETU Mechanical Engineering graduate students beat their rivals and won first place in the Turbofan Aircraft Engine Design Competition organized by Teknofest under the sponsorship of TR-Motor.

Baran İper, Burak Cenik, Çağdaş Cem Ergin and Tacettin Utku Süer, who carried out their graduate studies within the TOBB ETÜ Mechanical Engineering CSL Group (Combustion Systems Lab) in the Teknofest organization, the second of which is held this year and is the world's largest space-aviation festival, designed the 'ETÜ-GRİFFON Turbofan Engine 'won the first place.

Within the scope of the competition, it was aimed to develop the turbofan engine of a military jet aircraft by improving fuel consumption and thrust / weight ratios for 2029. With the turbofan engine they designed, TOBB ETÜ students successfully achieved all the requirements of the competition by reducing fuel consumption by an average of 18 percent for all task profiles and increasing the thrust / weight ratio by 10.5 percent. In addition, considering the developments in technology in 2029, the components of the turbofan engine were designed in detail, supported by Three Dimensional HAD (Computational Fluid Dynamics) analysis. As a result, ETÜ – GRİFFON Turbofan Engine; It is expected to save 14 million pounds over the total engine life by consuming 600 liters less fuel for a 72-minute flight.

A total of 1 million 720 thousand people attended Teknofest in 5 days, which was held with the slogan of the "festival with no feet on the ground", becoming the world's largest festival in this field. Aerospace to automotive, artificial intelligence from the simulation system, the water held in a broad spectrum extending the autonomous vehicle of the six vehicles in 19 different categories Situated technology competition from Turkey's 81 provinces, has made 17 773 team applications in total from 122 different countries and it deserves to be more than 2,000 teams of 50,000 contestants finalists won.

While 23 teams qualified to participate in the preliminary design, which is the first stage of the Turbofan Aircraft Engine Design Competition, which consists of 112 applications and consists of three stages, and 12 teams in the second stage, ETÜ-GRİFFON was invited to the presentation and the festival among the top 3 teams with the highest score at this stage. September 21 finals opponent that occurred in METU and leaving behind the Marmara University, first with students awards, Vice President Mr. Fuat Oktay and Turkey Technology Team (T3 Foundation) Board of Trustees received President of the Selcuk Bayraktar. The TurboFan Aircraft Engine Competition was sponsored by TR-MOTOR Power Systems, which was given the responsibility to develop the engine of the MMU (National Combat Aircraft) TFX.

Click for the details of the project.

TOBB ETU Mechanical Engineering Department students won the second prize with their ETU-V TULPAR design in the international engine design competition organized by AIAA (American Aeronautics and Space Institute) for the jet engine design intended to be used in a 100-seat passenger plane, which is planned to fly at supersonic speed in 2025.

2018

TOBB ETU Mechanical Engineering Department students Veli Can Üstündağ, Çağdaş Cem Ergin, Baran İper and Onur Tan, Mechanical Engineering, in the "Candidate Engines for a Next Generation Supersonic Transport" competition organized by AIAA (American Aeronautics and Space Institute), one of the world's most reputable aviation institutes. Department faculty member Dr. Sıtkı Uslu achieved great success in his consultancy.

Within the scope of the competition, a supersonic turbofan aircraft engine was designed, which has not yet been used in civil transportation in the world and has no similar application. In accordance with the design requirements, the engine is aimed to perform well at an altitude of 16000 meters at 1.6 Mach speed and the flight range to be at least 7500 km. Unwanted engine parameters such as fuel consumption, emission emission and noise of the engine designed in this direction have been reduced as much as possible and made in accordance with international standards. In addition, engine dimensions and weight have been optimized and significantly reduced due to technological developments and material improvements expected to be used by 2025. As a result of optimization, ETU-V TULPAR, which achieved 10.4% improvement in fuel consumption, 11.3% and 8.9% in engine weight and length, respectively, was designed to save 7 tons of fuel for a 10-hour flight and $ 3.5 million over the total engine life.

After the engine optimization studies, each component of the engine was designed in detail depending on its operating conditions. In addition to the main ingredients; Other sub-systems required for the engine such as lubrication system, turbine blades cooling system, engine starting system, anti-icing system, fire detection and extinguishing system, cooling and ventilation system were also investigated in detail.

The final presentations of the competition were made during the "AIAA Propulsion and Energy Forum 2018" held at Duke Energy Conference Center in Cincinnati, USA. Our students sponsor the conference where the final presentations were made, TR-MOTOR A.Ş. and KALE ARGE support.

We sincerely congratulate our students, who have not only viewed the project as a competition, but who have carried out their work with hard work and seriousness, for this international success they have won.

TOBB ETÜ's CSL Students Came in the First in the World at the AIAA's Competition

2015

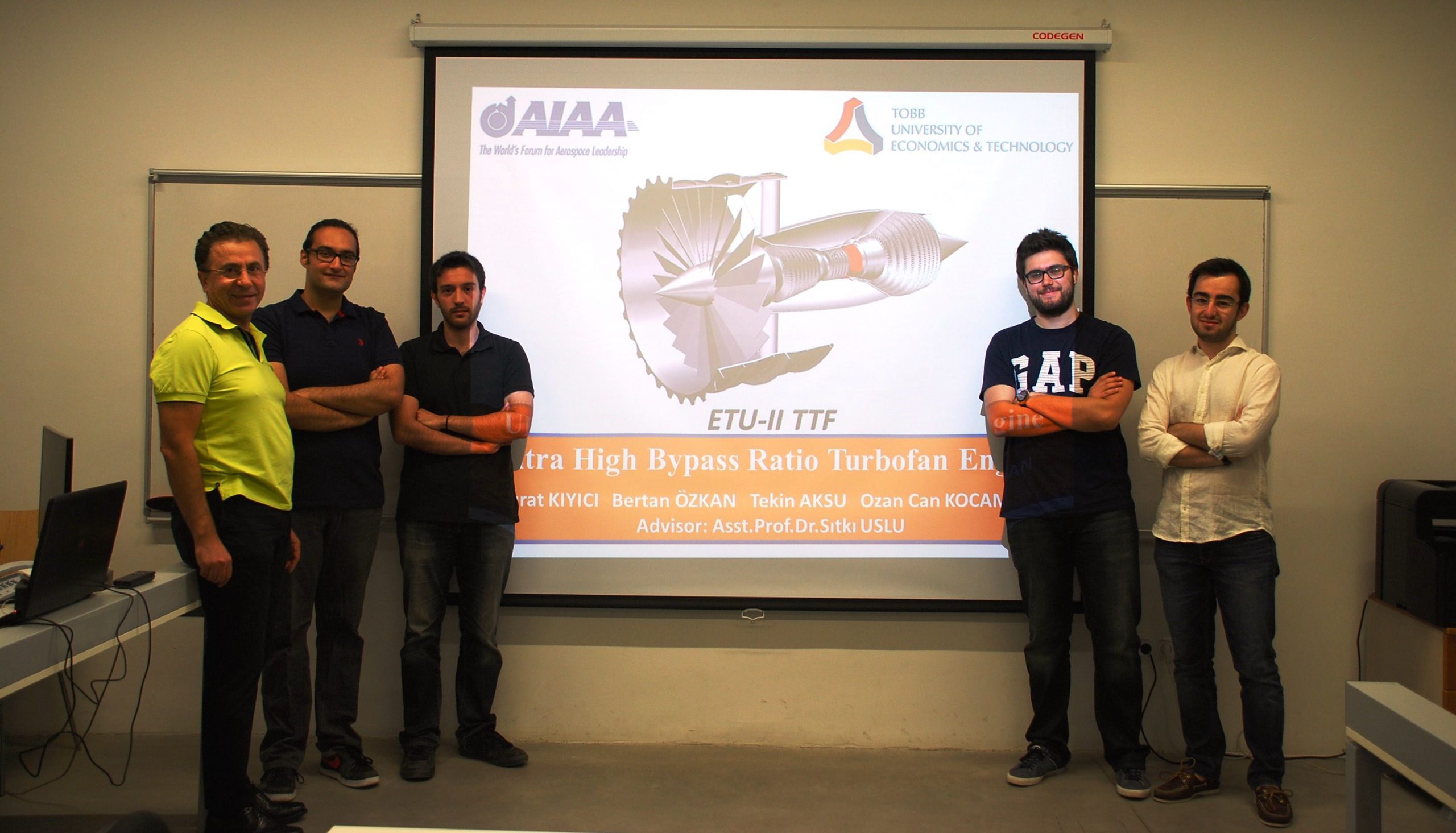

The students of the Department of Mechanical Engineering, TOBB ETÜ came in the first at the international competition held for the purpose of the design of an engine with a very high bypass ratio for Airbus A350, Airbus A380 and Boeing 787 airliners, the design and production of which is planned to be completed by 2025, with their design, titled ‘ETU-II-TTF’.

Fırat Kıyıcı, Bertan Özkan, Ozan Can Kocaman and Tekin Aksu, the students of the Department of Mechanical Engineering of our University, who worked on their design with the advisory of Assistant Prof. Dr. Sıtkı Uslu, achieved this brilliant success coming in the first at the international “Undergraduate Team Engine Design Competition 2015”, organized by the American Institute of Aeronautics and Astronautics-AIAA, being the most prestigious aviation institute in the world.

The final round of the competition was held during the “Propulsion & Energy Conference”, which was held in Orlando, Florida for the 51st time this year, and TOBB ETÜ's team was ranked the first, outscoring three teams from Embry Riddle University of the United States of America, the team of Kansas University as well as the team of Istanbul Technical University.

Assistant Prof. Dr. Sıtkı Uslu, a Faculty Member of the Department of the Mechanical Engineering, being the advisor of TOBB ETÜ's team, which prepared for the competition with the sponsorship support of our University and presented their design, provided the following information about the competition:

"The main objective of the competition was the design of a more efficient engine for the airliners, which are currently operated on flights and which have the minimum capacity of passengers. The primary design requirements of the competition were that the turbofan engine must be capable of performing satisfactorily at the altitude of 12 thousand meters, and also that such undesired engine parameters as engine fuel consumption, combustion emissions and noise must be optimized and reduced. The newly designed ‘ETU-II-TTF’ high by-pass ratio turbofan aircraft engine, which saves fuel by 16%, will consumer 21 tons of fuel less for a flight route of 22 hours.

Leveraging the experience we gained from our achievement at the last year's competition, at which we had come in third; this year, we focused more on the detailed design of the components of the engine, including the compressor, the combustion chamber, the turbine, the propelling nozzle and the computational fluid dynamics. We also developed designs, employing the computational fluid dynamics, for the cooling of the turbine blades (buckets= and the reverse propelling systems for landing. The students did not consider the project merely as a competition material but carried out the endeavor devotedly and with a great deal of focus, and also authored an international congress paper on the basof the project."